It is possible to produce large-volume components from different materials. Sheet material is used as the initial material, which is cut using laser, milling cutter or oscillation knife and then joined layer by layer to the component with matched adhesives. Industrial robots are used to automate this manufacturing process. Support structures and waste are strategically minimized and not connected to the component via glue, which allows a slight mechanical removal.

The Z-resolution of the Syncree system is between 1 and 10 mm. The current layer is created by separating and joining in one operation. This leads by large-volume components to shortened manufacturing times and reduced manufacturing costs. The step formation is propagated in the furniture sector as a design feature of the Syncree products. But there is also the possibility of eliminating these by adjusting the angle of the cut edges. The maximum workable area for the cutting process is currently 2000 × 2000 mm. The height of the joining process is basically only limited by static conditions, which can be compensated by internal auxiliary structures that can also remain in the component. The additive system is primarily designed for products in the Furniture sector, but can also be used in other areas: Automotive, Exhibition and Packaging

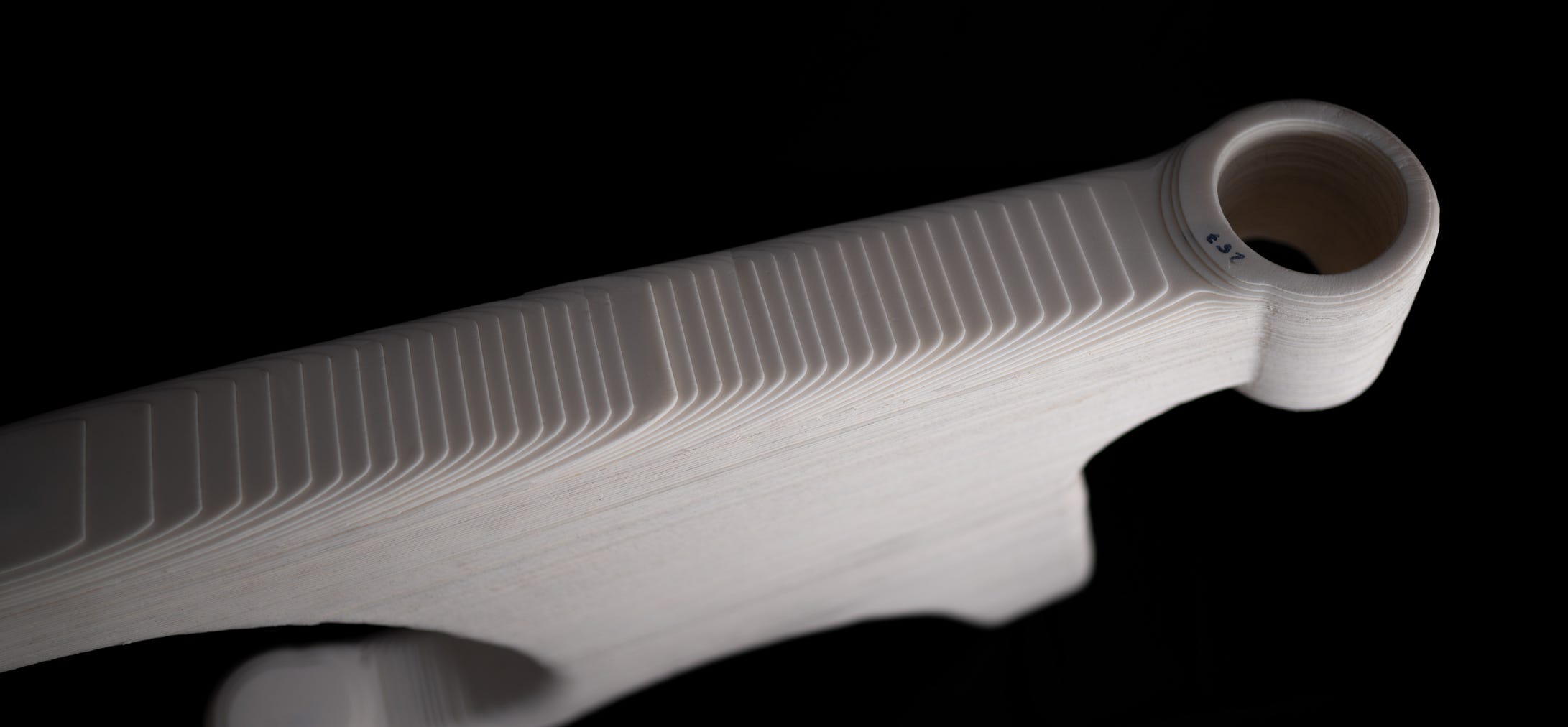

Prototype 00

The first big object that syncree created via Layer Laminated Manufacturing.

Designer: Andreas Fischer

Dimensions: Length 97 cm, Width 10 cm, Height 65 cm

Layer: 2,5 mm

Material: Polyethylene foam

Edition: Prototype

Price: Basis for negotiation